Date:2025-07-23 Views:1001

In metal manufacturing, process selection directly impacts product quality, production efficiency, and cost control.

Conventional processes and Metal Injection Molding (MIM) represent two significant manufacturing methods, each with distinct characteristics and application scenarios.

A broad concept encompassing various metalworking methods:

Forging: Uses external force to plastically deform metal blanks into workpieces with specific shapes, dimensions, and mechanical properties.

Casting: Pours molten metal into a mold cavity, solidifying it into the desired part shape.

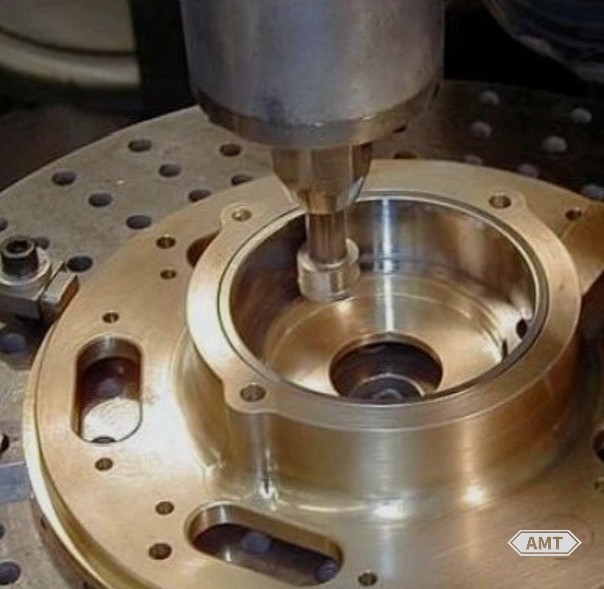

Machining: Removes material from a workpiece using cutting tools to achieve precise dimensions and shapes.

Combines fine metal powder with polymer binders to create moldable feedstock.

Injects feedstock into custom-designed molds to form green parts.

Removes binders (debinding) to create brown parts, then sinters them into high-density, high-precision, complex-shaped metal components.

Cost structures differ significantly due to material, tooling, and post-processing factors:

Cost Factor | Conventional Processes | MIM |

Material Costs | Lower material prep cost but high waste (e.g., machining scrap). | Higher feedstock cost (ultra-fine powders + binders) but 95% material utilization minimizes waste. |

Tooling Costs | Lower for simple shapes; economical for small batches. | Higher upfront cost (complex molds accounting for shrinkage and more complicated design), but amortized in high-volume production. |

Post-Processing | Multiple operations needed for complex parts → higher labor & machining costs. | Near-net-shape output → minimal finishing (high density, precision, surface finish). |

Efficiency is critical for evaluating manufacturing processes:

Efficient for simple parts (e.g., batch casting) but slow for complex geometries (multi-step processing, setups, low automation).

Prone to human error → ↓ productivity.

Automated production line (feedstock prep → injection → debinding → sintering) enables continuous flow.

Complex parts formed in single operation → shorter cycle times.

High consistency → minimal rework/scrap.

Efficiency advantage amplifies at scale.

Forging: High-strength, high-toughness parts (e.g., crankshafts, connecting rods).

Casting: Large, complex parts with relaxed tolerances (e.g., machine beds, valve bodies).

Machining: Precision simple geometries (e.g., shafts, discs).

Complex miniature parts (watch components, surgical tools, connectors) with intricate features (internal cavities, threads, thin walls).

High-precision/high-performance parts requiring tight tolerances, superior surface quality, or special properties (wear/corrosion resistance via alloy flexibility).

High-volume production (automotive/consumer electronics) with cost efficiency.

MIM is revolutionizing metal manufacturing by offering lower cost, higher efficiency, and superior precision for complex parts, displacing conventional methods in aerospace, automotive, medical, and electronics industries.

Adopting MIM enhances product quality, reduces costs, and strengthens market competitiveness.

Leave your email for more ebooks and prices📫 !

Contact:Fidel

Tel:021-5512-8901

Mobile:19916725893

Email:sales7@atmsh.com

Address:No.398 Guiyang Road Yangpu China