Date:2025-07-30 Views:0

Traditionally, implants were secured with polymethyl methacrylate (PMMA) cement. The surgical procedure involves preparing a cavity of precise dimensions in bone, placing viscous, partially cured PMMA into the cavity, inserting the implant, and allowing the PMMA to cure and lock the implant in place—essentially a mechanical fixation.

The cement penetrates the surrounding bone and interlocks with microscopic irregularities on the implant surface. Shrinkage during curing further secures the cement within the implant. Over time, however, the implant loosens within the cement. This loosening can be painful or can increase stresses on the implant, leading to failure and the need for revision surgery.

To eliminate loosening, implants now incorporate rough or porous surface coatings. Porous-coated implants can be fixed either by cement bonding to the porous layer or by osseous ingrowth into the pores.

For mineralized bone to grow into the porous coating, pore interconnectivity must exceed a minimum size. If pores are smaller than this threshold, only soft tissue forms or no ingrowth occurs at all. These minimum pore dimensions reflect biological constraints. Studies on the minimum interconnecting pore size show some variation, influenced by material characteristics and the animal model used. For unloaded implants, the minimum interconnecting pore size is about 50 µm. For loaded devices—such as artificial hips or knees—healthy bone support requires interconnecting pores of 100–150 µm. When porous coatings are produced by sintering powder particles, pore size is controlled through powder-particle selection.

Several processes have been developed to apply porous coatings. Cobalt-chromium or titanium powders can be blended with various binders, coated onto Co-Cr or Ti alloy implant surfaces, and then sintered. Wire or fiber preforms can be shaped into porous pads and diffusion-bonded to titanium-alloy implants. Sacrificial pore-forming agents are also used to create porous metals. Plasma spraying and porous polymer coatings have likewise been employed.

The conventional sintering technique that bonds coarse powder particles (–841 µm + 325 µm, –20 + 45 mesh) to Co-Cr alloys typically operates at 90–95 % of the base-metal melting point. Such high-temperature exposure significantly affects the microstructure and properties of fine-grained, high-strength implant materials—such as HIP-consolidated metal powders or wrought Co-Cr-Mo alloys—usually causing severe grain growth and reduced fatigue strength. Currently, porous powder coatings are applied to coarse-grained cast implants, so their fatigue strength is lower than that of HIP Co-Cr-Mo alloys. The porous layer can also act as a notch, further lowering fatigue strength.

A modest reduction in fatigue strength is acceptable because bone ingrowth provides excellent fixation and load sharing between implant and bone. Proper implant design can prevent excessive fatigue degradation. Clinical requirements—such as insertion and extraction—must also be considered.

Research is under way on compositional modifications and combined temperature–pressure cycles that lower sintering temperatures. These approaches allow diffusion bonding of porous titanium-fiber pads to titanium implants at temperatures far below conventional gravity sintering.

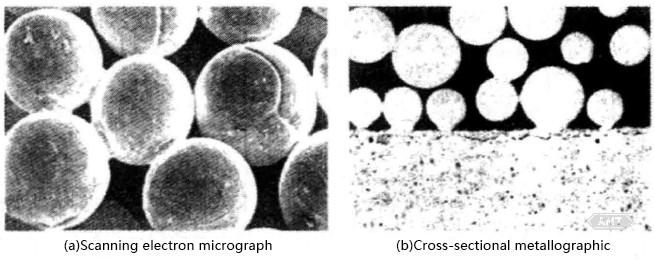

Figure 10-10 shows scanning-electron and cross-sectional metallographic images of sintered Co-Cr-Mo particles. Note the necks formed between particles and the clear particle-to-particle bonding in the cross-section.

Figure 10-10 Scanning electron micrograph and cross-sectional metallographic image of sintered cobalt–chromium–molybdenum alloy particles

Figure 10-11 presents a cross-section of a canine femoral knee implant with a Co-Cr powder coating after nine months in vivo. The pores are filled with well-developed bone. This fixation is superior to mechanical fixation with PMMA cement.

Figure 10-11 Cross-section of a canine femoral knee implant with a cobalt–chromium powder coating after 9 months of implantation, showing well-developed bone growth within the pores.

Although porous-coated hip and knee implants receive the most attention, other devices also benefit. For example, cardiac pacemakers can be secured using porous coatings in which soft-tissue ingrowth provides fixation.

Leave your email for more ebooks and prices📫 !

Contact:Fidel

Tel:021-5512-8901

Mobile:19916725893

Email:sales7@atmsh.com

Address:No.398 Guiyang Road Yangpu China